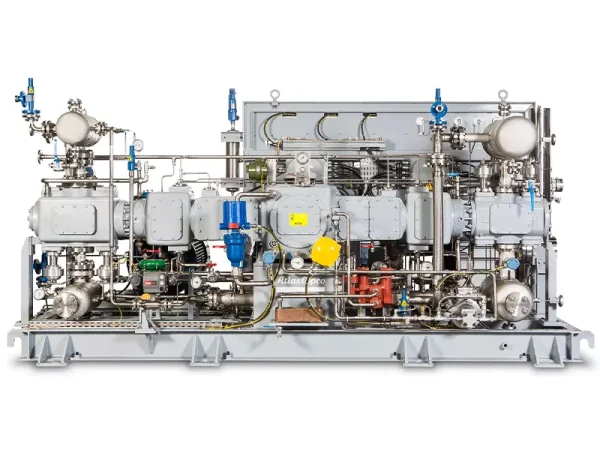

Oil-free Screw Air Compressors ZR & ZT (VSD)

Our oil-less compressors are also class 0 certified, delivering the highest air purity at the lowest total cost of ownership. By using our rotary screw technologies you are guaranteed a reliable and efficient compressor.

Brand:

Description

Oil-free Screw Air Compressors ZR & ZT (VSD)

Industrial rotary screw and rotary tooth oil-free air compressors 3,5 to 13 bar

-

Certified oil-free air

-

Meets the top quality standard in the food & beverage industry

-

Energy savings up to 35%

-

Fast & easy set-up

-

Optimal reliability

-

Global presence – local service

Oil-free screw compressor designed for energy efficiency

The components of the ZR/ZT oil-free rotary screw air compressor range have been carefully designed in-house. This reduces losses and pressure drop to a minimum, resulting in the highest compressor package efficiency.

Our oil-less compressors are also class 0 certified, delivering the highest air purity at the lowest total cost of ownership. By using our rotary screw technologies you are guaranteed a reliable and efficient compressor.

Variable speed drive (VSD) energy savings add up

Over 80% of a compressor’s lifecycle cost is taken up by the energy it consumes. The generation of compressed air can account for more than 40% of a plant’s total electricity bill.

To cut your energy costs we have pioneered Variable Speed Drive (VSD) Technology in the compressed air industry. Atlas Copco’s VSD technology closely follows the air demand by automatically adjusting the motor speed. This results in energy savings of up to 35%.

Recover your energy

You can turn your compressor into an energy source. Our water-cooled screw compressors can be equipped with an Energy Recovery Unit. This will help you achieve your goal of becoming carbon neutral.

Up to 94% of the electrical energy is converted into compression heat. Without energy recovery, this heat is lost in the atmosphere via the cooling system and radiation. Our energy recovery unit uses compression heat to heat up water.

This warm water can be used for sanitary purposes, space heating, or process applications.

Save energy with smart technology

Our compressor monitoring system saves energy by using advanced control algorithms. Our delayed second stop function uses air demand data to stop the compressor whenever possible. The dual pressure band can lower the pressure in your system during e.g. weekends and night shifts.

Our Elektronikon® controller is the brain of the compressor collecting data for optimal energy efficiency.

Monitor your system

It’s important to know the status of your compressed air systems. With the Elektronikon® you can easily connect your controller with your mobile devices such as tablets and smartphones.

Featured Products

JD Fans - The Best Solution to Significantly improve the environmental comfort.