Atlas Copco High Pressure Filtration

Compressed air systems are always at risk of contamination. Dust, wet dust, oil aerosol, water droplets, particulates and oil vapor pose a threat to downstream equipment and end products.

Brand:

Description

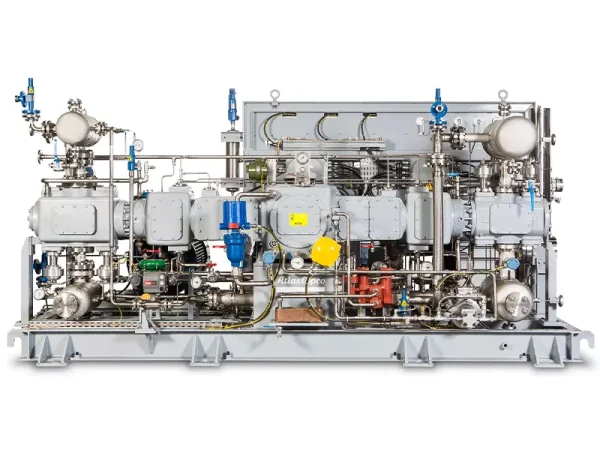

HIGH PRESSURE FILTRATION

Compressed air systems are always at risk of contamination. Dust, wet dust, oil aerosol, water droplets, particulates and oil vapor pose a threat to downstream equipment and end products.

- Wrapped technology

- Maximum durability

- Lowest pressure drop

- 8000hr service intervals

High pressure filtration

Regular filters that take on one group of contaminants each, Atlas Copco has also developed high-pressure air filter variants that guarantee air purity up to a pressure of 350 bar: The H series. They efficiently reduce contaminants in a high-pressure environment in a cost-effective manner.

H series

This high-pressure filtration solution has been engineered to cost-effectively reduce a wide range of contaminants in your compressed air stream. As a result, they provide you with the best air purity and meet even stringent quality demands for working pressures of up to 350 bar.

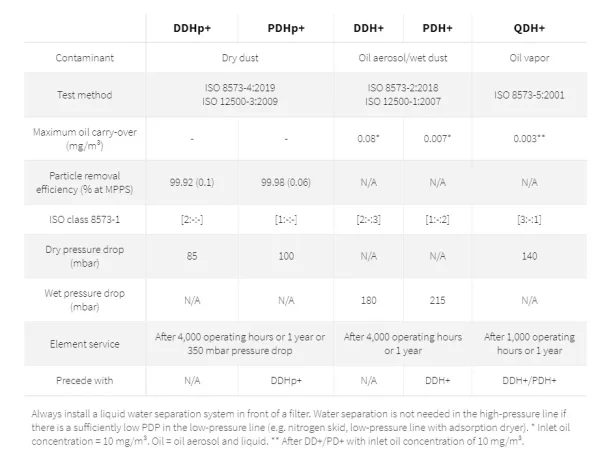

All filter housings of the H series are hydraulically tested to always ensure a safe and reliable operations. Using high-efficiency glass fiber and fleece media, they ensure a maximum removal of dry and wet dust, particulates, oil aerosol and water droplets (depending on which model you choose. Please consult the table below). As a result, the H series provides optimal protection for your compressed air stream, downstream equipment, and end products.

The low pressure drops of these high-pressure air filters offer you substantial energy savings and lower operating costs. In addition, thanks to high-performance stainless-steel cores, double O-rings, epoxy-sealed caps, and a filter housing with an anti-corrosive coating, they are also extremely reliable.

Performance

Featured Products

JD Fans - The Best Solution to Significantly improve the environmental comfort.