Description

PERFECT BODY BLANKS FOR TROUBLE-FREE CANMAKING LINES

SLITTERS AND BODY BLANK TRANSFER UNITS

BODY BLANK TRANSFER SYSTEMS AND SLITTERS FOR HIGH PRECISION AND FAST OUTPUT.

When it comes to versatility, precision, reliability and production speed, our slitters are second to none.

In a typical canbody production line, the slitter is the first stage in the manufacturing process. It cuts printed and lacquered metal sheets into body blanks of the required size. The addition of a blank stack transfer unit further increases the slitter’s efficiency. They are extremely robust, facilitate simple, swift adjustment to different blank formats and ensure exceptionally high precision.

Body blank transfer systems play a crucial role in any fully auto- mated canbody production line. Our automatic transfer units fulfil the most stringent demands.

Our transfer systems feed the blank magazine of the canbody welder with cut blanks from the slitter. Thanks to its substantial reserve capacity for blanks, the transfer unit can compensate for short upstream or downstream production interruptions, thus guaranteeing non-stop operation of the production line. With a feeding capacity of up to 1500 blanks per minute, our transfer systems are suitable for all system layouts and configurations.

OCSAM SGS 120 COMBINED GUILLOTINE/ROTARY CUTTERS

The ideal slitter for aerosol and general line can producers.

- Completely automatic and instantaneous body blank height changeover

- Body blank length changeover in just a few minutes

- Possibility to store and recall hundreds of different sheet-cutting layouts

- State-of-the-art technology such as linear motors, servo motors, high-speed hydraulics, touch-screen panel and a revolutionary wear and maintenance-free guillotine ram guide system

SGS 120 guillotine/rotary slitter connected to an RAS-3 automatic blank stacker in a fully integrated version. In this set-up both units are controlled by a single, extra-large touch-screen panel.

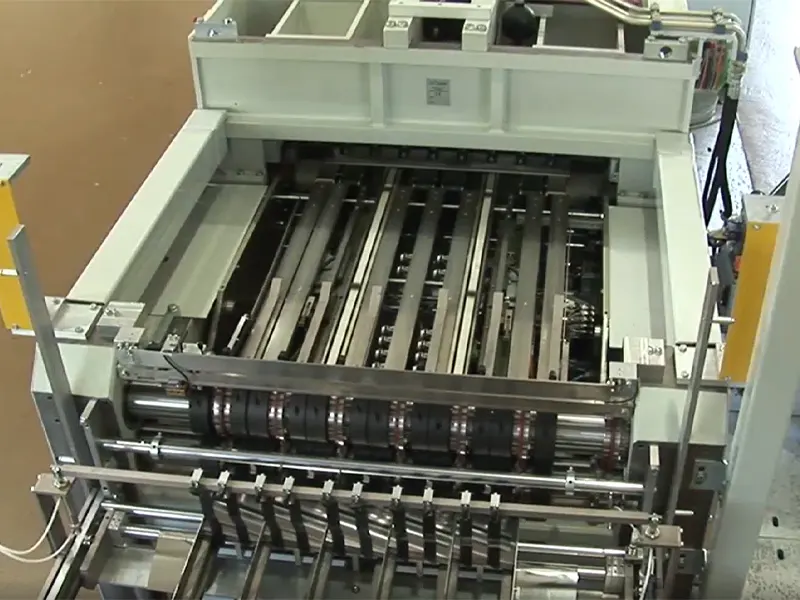

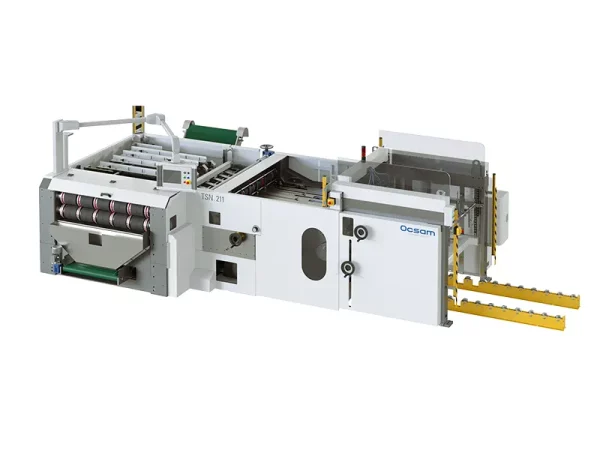

OCSAM TSN211 DUPLEX SLITTER

The ideal duplex slitter for any canmaking line, a «must» for high-speed lines.

- State-of-the-art technology

- Maximum speed

- High-level precision

- Outstanding efficiency

- Perfect handling of thinnest plate

- Strips handled by drop-bars or electro-magnetic bars

- Fully automatic synchronization between sheet-feeder / feeding belts / sheet centering device / drop bars (or electro-magnets) and second table chains

- Possibility to store and recall different sheet cutting layouts

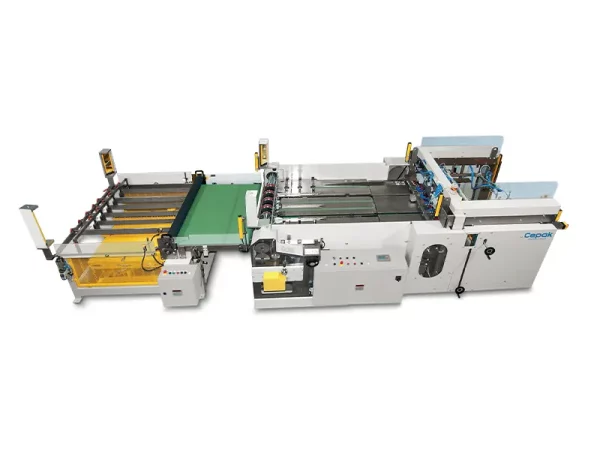

Duplex TSN 211 slitter connected to TPM blank transfer unit in a fully integrated configuration. This integrated version is available for a TSN 211 connected to any TPM/ TPM-S units. In this set-up both units are controlled by a single touch-screen panel.

CEPAK 110 MK2/1 SINGLE SLITTER

High precision, high-speed automatic single slitter.

- Available for tinplate and/or aluminum sheets

- Easy to operate and to maintain

- Outstanding cutting accuracy and highest efficiency

- Dependable and sturdy

110 MK2/1 single slitter connected to an RAS-4 automatic strip stacker (also available with driven or undriven outlet conveyor).

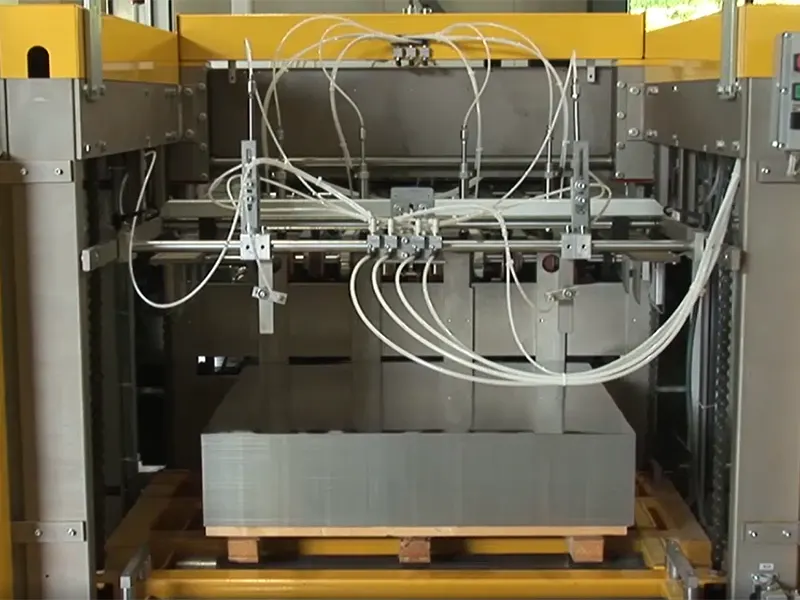

BODY BLANK TRANSFER UNITS

ST AND-ALONE VERSIONS

TPM-S

- The fastest, most advanced and flexible transfer unit

- Custom executions to match any line layout

- Able to feed simultaneously two welders running the same blank size (see picture)

TPM

The upgraded body blank transfer unit featuring:

- Built-in blank stack over-turning or non- over-turning options

- Pivoting transfer arm

- Rotating pincer to match any line layout

- Touch-screen panel on pivoting arm

TECHNICAL DATA

DUPLEX SLITTERS

| S.P.M. | MM | MM | STRIPS | MM | MM | |

| OCSAM TSN211 BSS

Back Squaring System Left or right-hand version |

10–50 | W 580–1180

L 600–1130 |

0.12–0.40 (*) | 1–7 | 140–600 (*)

Ø 45–189 |

56–1200 |

SINGLE SLITTERS

| S.P.M. | MM | MM | STRIPS | MM | |

| CEPAK 110 MK2/1

Single Rotary Slitter |

10–50 | W 530–1160

L 550–1130 |

0.12–0.40 (*) | 1–18 (*) | 68–1160 (*) |

COMBINED GUILLOTINE/ROTARY CUTTERS SLITTER

GUILLOTINE STROKES MM MM MM MM

OCSAM SGS 120 max 150/min W 650–1150 (*) 0.14–0.40 (*) 56–1150 45–550

L 450–1100

STRAIGHT GUILLOTINE SLITTER

GUILLOTINE STROKES MM MM STRIP HEIGHT

OCSAM SGS 1 max 150/min W 650–1150 (*) 0.14–0.40 (*) 45–550

L 450–1100

(*) Variations or extended range upon request

TECHNICAL DATA

BODY BLANK TRANSFER UNITS (BY BLANK STACKS)

| CYCLES/MIN | MM | MM | HEIGHT MM | |

| OCSAM TPM-S

Left or right-hand version |

3.0 max (°) | 140–520 (*)

Ø 45–165 |

75–300 (*) | 75 max |

| OCSAM TPM

Left or right-hand version |

2.0 max (°) | 140–520 (*)

Ø 45–165 |

75–300 (*) | 75 max |

STRIP/BLANK STACKERS

DESCRIPTION

REN-3 Blank stacker with pneumatic ejection of the blank stacks

RAS-3 Automatic blank stacker with hydraulic table. It stacks blanks in multiple rows: allowing to collect one full pallet of perfectly stacked blanks

RAS-4 Automatic stacker with or without hydraulic table. Suitable for strips and blanks.

(*) Variations or extended range upon request (°) 1 cycle = 1 blank stack transferred to the welder magazine

ACCESSORIES

- Driven roller infeed platform

- Cutter grinder

- Digital measuring device for quick and precise setting of the cutters

- Lacquer margin control device

- Magnetic trim removal device

Featured Products

JD Fans - The Best Solution to Significantly improve the environmental comfort.