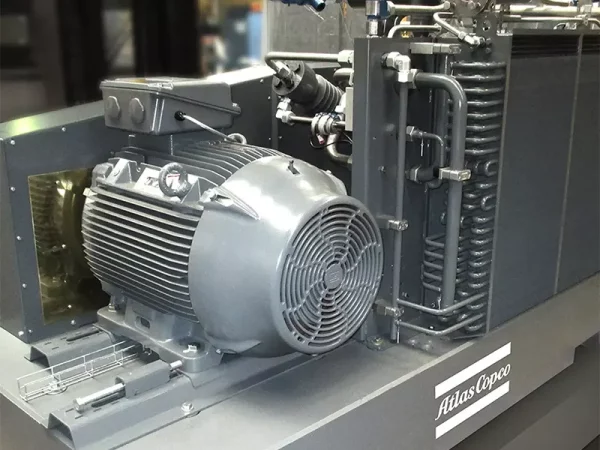

Atlas Copco Dust Filtration

Dust is all around us, which is why it is one of the most common threats to compressed air systems. To protect you and your investments from dust, Atlas Copco has developed a series of top-quality air filters.

Brand:

Description

DUST FILTRATION FOR YOUR AIR COMPRESSOR

Dust is all around us, which is why it is one of the most common threats to compressed air systems. To protect you and your investments from dust, Atlas Copco has developed a series of top-quality air filters.

- Wrapped technology

- Maximum durability

- Lowest pressure drop

- 8000hr service intervals

Dust filtration for your air compressor

Once dust (or other contaminants like particulates and micro-organisms) enters your compressed air stream, it can have detrimental – and costly – consequences for your downstream equipment and end products.

To protect you and your investments from dust, Atlas Copco has developed a series of top-quality air filters. They ensure that your operation runs smoothly, your equipment lasts longer, and your end products meet even the highest quality standards.

Know your air quality requirements

Find out some useful information on the performance of the DDp+/PDp+ series below.

If you are unsure, and only know that you have to protect your system from dust, then you need to find out your air quality requirements. For some applications, such as inflating tires, some contaminants in the compressed air do not pose any problems. Others, such as applications in cleanroom environments, require the highest air purity.

Knowing your air quality requirements and which standards to comply with will help you select the right air filter, which could lower your investment costs and ensure that you get the most out of your compressed air system. If you are not sure which ISO standard applies to your operation or which type of contaminant you have to protect your system from, you can contact JC Domingo Enterprises Corporation or consult the two tables below.

Performance

| Specifications | DDp+ | PDp+ |

|---|---|---|

| Contaminant | Dry dust | Dry dust |

| Filtration technology | Pleated | Pleated |

| Test method | ISO 8573-4:2001, ISO 12500-3:2009 | ISO 8573-4:2001, ISO 12500-3:2009 |

| Particle removal efficiency (% at MPPS) | 99.92 | 99.98 |

| ISO class 8573-1 | [2:-:3] | [1:-:2] |

| Average dry pressure drop (mbar) | 49 | 56 |

| Element service | After 8,000 operating hours or 1 year or 350 mbar pressure drop. For flanged filters: after 4,000 operating hours or 1 year or 350 mbar pressure drop. | After 8,000 operating hours or 1 year or 350 mbar pressure drop. For flanged filters: after 4,000 operating hours or 1 year or 350 mbar pressure drop. |

| Precede with | Dryer | Dryer and DDp+ |

Featured Products

JD Fans - The Best Solution to Significantly improve the environmental comfort.